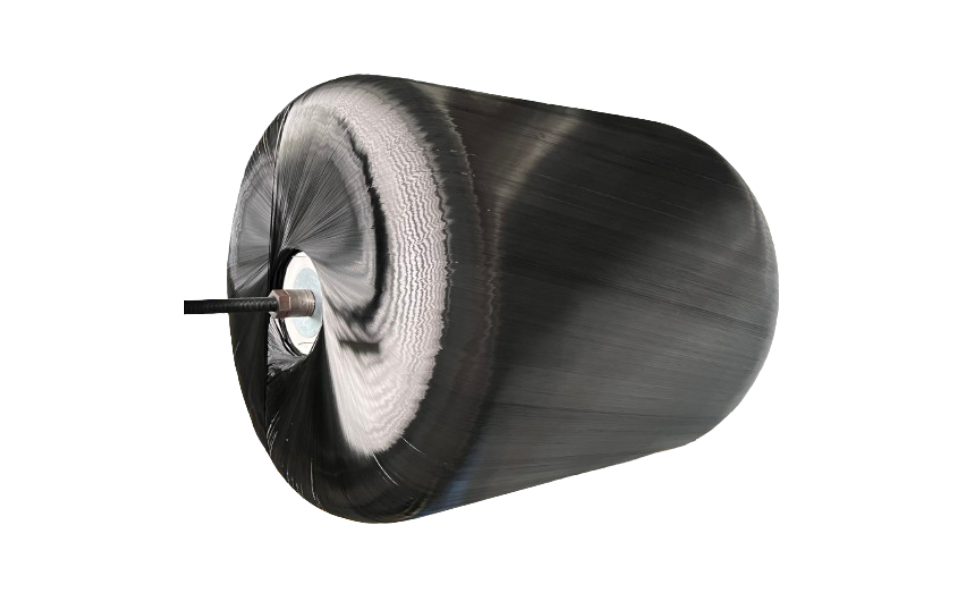

Charcoal crucible carries quartz crucible to maintain stable liquid level. As a carrier of molten silicon material, it is lightweight, has strong corrosion resistance, high service life, high cost-effectiveness, and can effectively reduce energy consumption in the crystal pulling process. The company has made a breakthrough by adopting winding and needle punching technology, with fully automated operation to ensure continuous and uniform fiber stress, optimize needle punching density, significantly reduce fiber damage and delamination, and significantly improve the overall strength of crucible preforms.

① Wrapping and needling process

② Can be customized as needed, with a maximum weaving diameter of up to 1.5 meters

③ The service life is extended by more than four months compared to traditional products