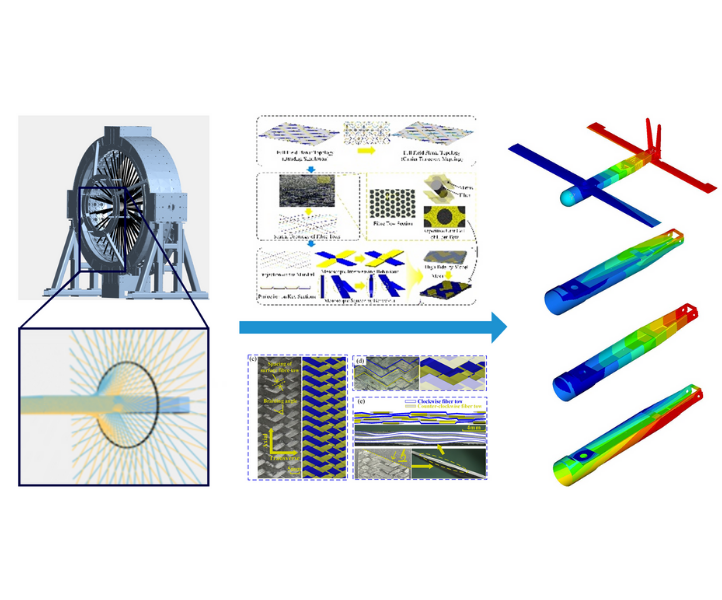

In partnership with Donghua University, Yunlu Composites has achieved a series of breakthroughs in 3D braiding technology. We have mastered large-scale spindle-phase ground-propagation algorithms, friction-reduction techniques for speciality fibres, high-curvature eccentric-braiding control, multi-scale rapid 3D braiding simulation and real-time attitude control of 3D braiding mandrels. Our current radial 3D braiding machines accommodate a broader range of fibre types, handle thicker preforms in a single pass, cover a wider size range on the same machine and deliver higher dimensional accuracy—up to 9 m in diameter and 1 000 spindles.

Any mandrel geometry can be reconstructed in 3D, allowing instant generation of theoretical tow-path orientations and speeds across the entire braiding cycle. The resulting fabric architecture is simulated and predicted. The secondary calculations correct tow speeds at mandrel bends before trajectory, velocity and other control files are exported to the production line.

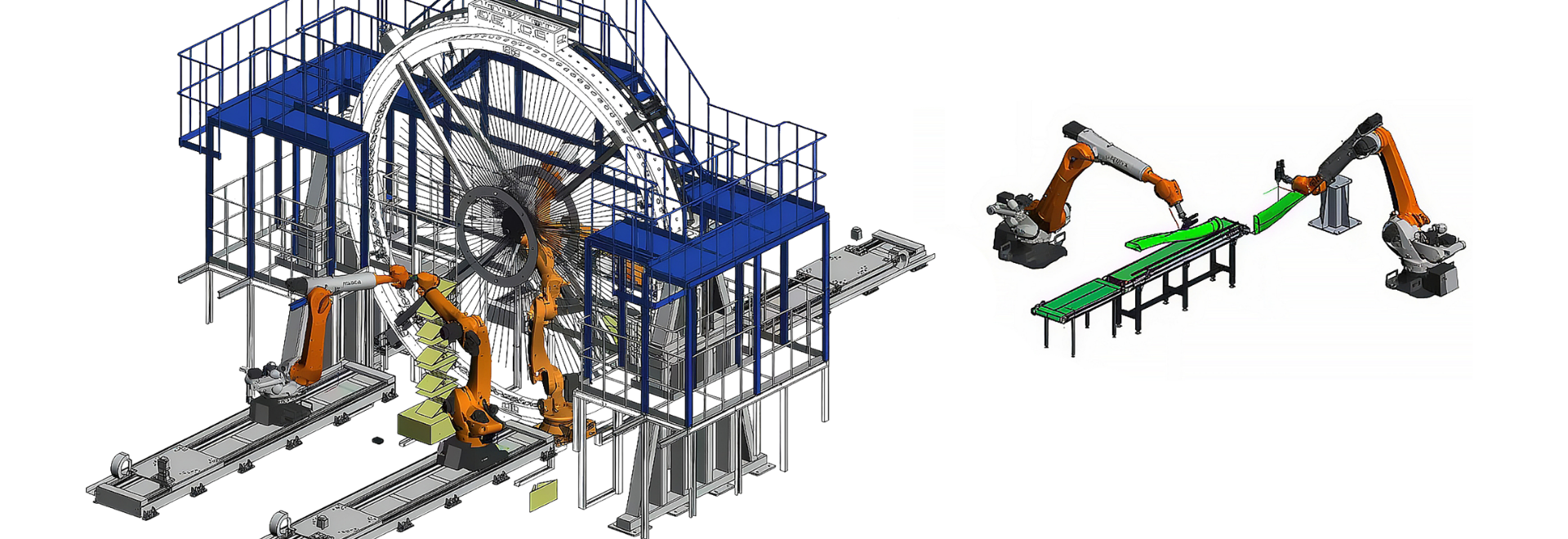

Based on our current equipment portfolio, production capacity and product characteristics, our manufacturing routes are grouped into four primary processes: 3D-braiding / 3D-weaving preforms + compression moulding / RTM injection: Ideal for both simple and highly complex resin-matrix composite parts in large volumes—typical for sports equipment. 3D-braiding / 3D-weaving preforms + vacuum infusion: Suited to low- and medium-volume or bespoke orders—common in defence, aerospace and similar sectors. Braid–ply–wind–pultrude integrated line: A fully automated, continuous process for constant-section resin-matrix profiles delivered at high volume. Needled / stitched preforms: Used as the precursor for carbon- or ceramic-matrix composites offering outstanding insulation and wear resistance—applied in photovoltaic thermal fields, aerospace, automotive, etc. Intelligent needling or stitching equipment enables rapid, efficient manufacture of both regular and highly contoured preforms.

We operate a fully equipped test laboratory offering end-to-end capability: raw-material qualification, product-performance verification and non-destructive evaluation. Equipment includes Charpy impact testers, universal testing machines, drop-weight testers, muffle furnaces, DSC, Vicat softening-point apparatus, needle-flame tester, horizontal/vertical flame test chamber, CMMs, multi-sensor vision systems, blue-light scanners, digital X-ray imaging, ultrasonic inspection systems, salt-spray chambers and high-/low-temperature test cabinets, among others.