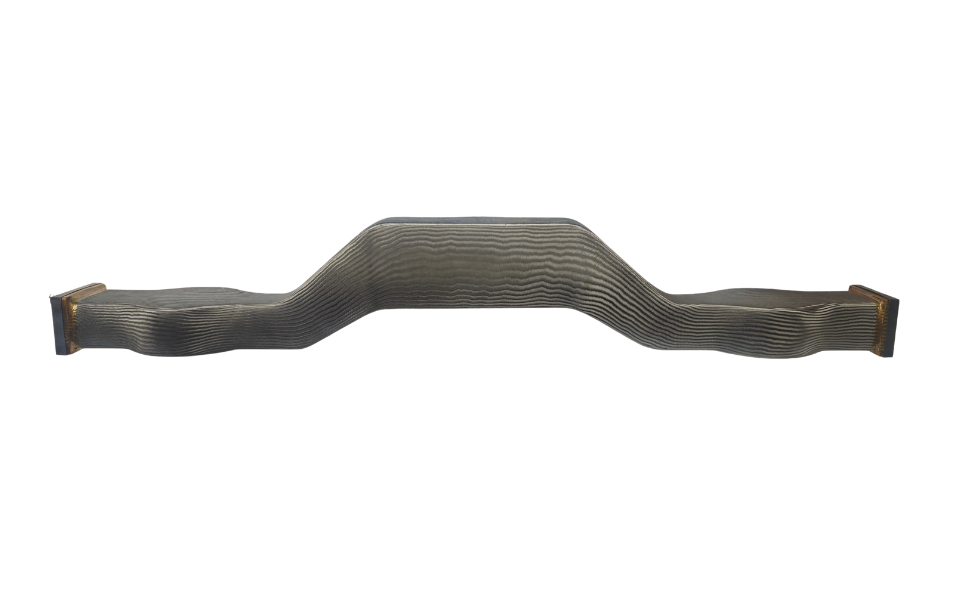

The subway bogie side beam independently developed by the company adopts three-dimensional weaving technology to ensure excellent fiber continuity and structural integrity of the product. By using a large-sized irregular structure 3D weaving machine and dual robot collaborative control of the core mold posture, the one-time mass production of ultra large carbon fiber composite components has been achieved. By combining multiple composite processes, the technical bottleneck of resin infusion and penetration in thick and complex three-dimensional structures has been effectively overcome. This component reduces weight by more than 50% compared to traditional metal frames, significantly improving safety and service life while meeting the comprehensive performance requirements of bogie side beam strength, stiffness, and toughness.

① 3D weaving

② Excellent fiber continuity performance

③ Reduce weight by over 50% compared to traditional metal frames